Investigating "The Way" for Toyota Suppliers: A Quantitative Outlook on Toyota's Replicating Efforts for Supplier Development

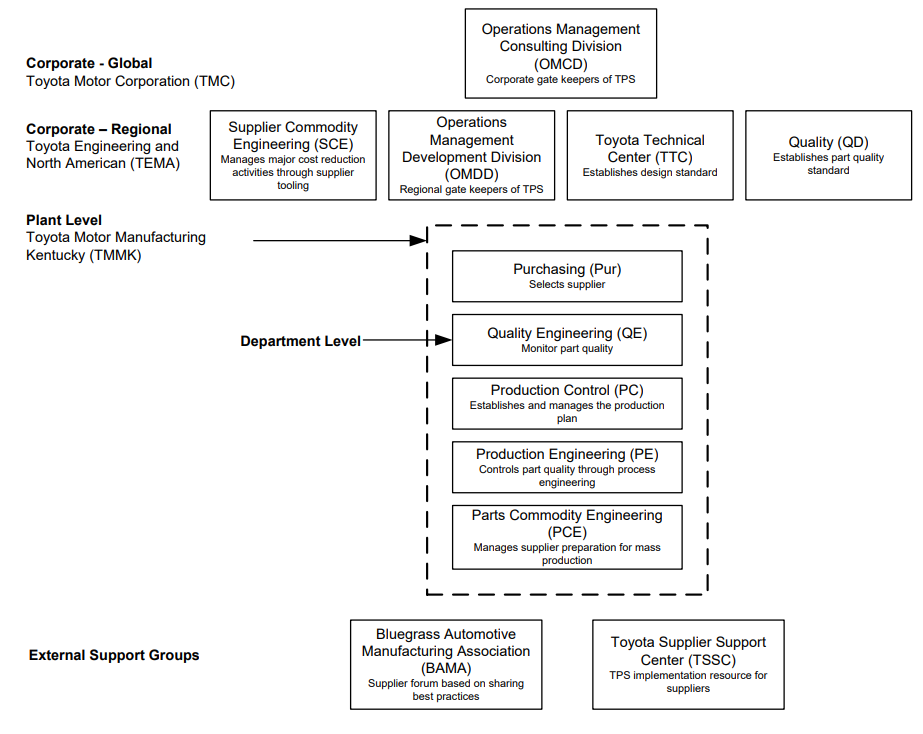

Toyota's management system, more formally known as the Toyota Production System (TPS) is one of the most benchmarked business improvement strategies in modern industry. While many companies try to emulate Toyota’s success using a variety of different approaches, most practitioners are not aware how Toyota replicates TPS at suppliers. This work investigates the in-house capabilities that are transferred from Toyota to suppliers as a way to more deeply understand how TPS can evolve. This work utilizes a form of data mining to analyze Toyota’s initial practices employed in supplier development. This work shows that Toyota targets processes, rather than whole systems, in assisting suppliers to be more effective at abnormality management. Findings also show that Toyota’s approval process doesn’t necessarily support major kaizen at suppliers yet does encourage minor day-to-day kaizen. Finally, this work reports that the Toyota Way for suppliers, does not have to be adopted by suppliers, but does represent “A Way” to interact with suppliers to drive both culture and productivity simultaneously. These new insights and others, provide an increased understanding of Toyota’s supplier development practices that relate to the implementation of TPS.