Managing the IE (Industrial Engineering) Mindset: A quantitative investigation of Toyota’s practical thinking shared among employees

(PDF) Managing the IE (Industrial Engineering) Mindset: A quantitative investigation of Toyota’s practical thinking shared among employees. Available from: https://www.researchgate.net/publication/269475060_Managing_the_IE_Industrial_Engineering_Mindset_A_quantitative_investigation_of_Toyota's_practical_thinking_shared_among_employees [accessed Nov 02 2024].

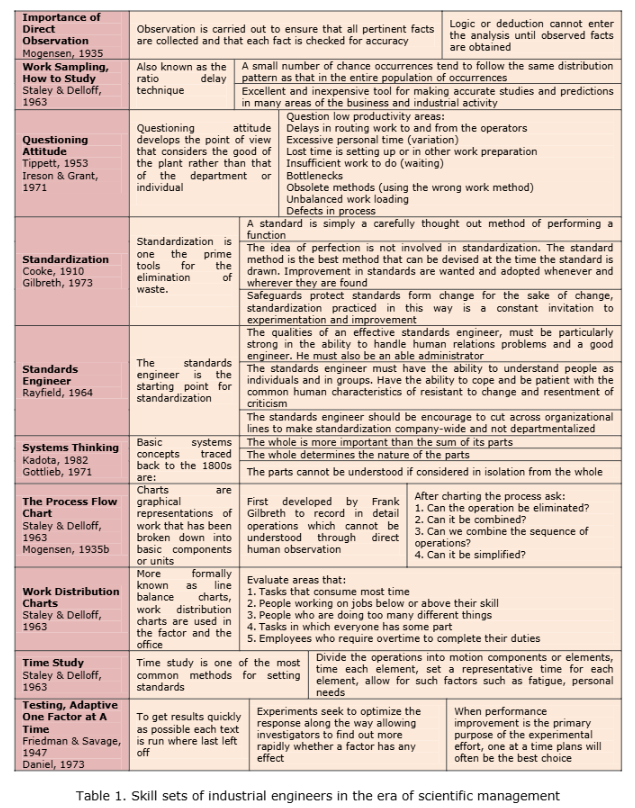

Toyota's management system, more formally known as the Toyota Production System (TPS) is a modern technology aimed at reducing cost and eliminating waste. TPS, which is more commonly known as lean manufacturing, initially originated on the production floor, where several tools such as 5S, visual control and standardized work were created. Over the last decade, lean has grown from a manufacturing philosophy to a business strategy. Currently, companies all over the world are in a state of kaizen to modernize their accounting systems, design practices, maintenance areas and human resource functions to emulate their business systems like Toyota. While few researchers see gain in holding interest on a particular aspect of TPS, most consultants and authors actively seek new ways to apply lean in uncharted areas of the business. This craze to upload lean into all aspects of the business has weakened organizations mainly because practitioners insist on applying the manufacturing tools of lean (i.e. visual control, 5S, standardized work) rather than applying the thinking of lean. What is unique about Toyota's system is not particularly any single piece of TPS, but how the pieces are combined to bring out something new, different and very difficult to imitate. So much work has been completed in examining and dissecting the parts of the Toyota Production System that little has been done to examine how the parts work together! It is argued in this work that Toyota's management system is a richly interconnected set of parts and relationships that are more important than the nature of the parts themselves. This means that even if the parts themselves can be identified, their relations are often lost, which loses meaning of the system. It is believed that research in TPS must follow the same type of systems thinking to discover how TPS emerges from the way the parts are organized in the system. Holism, rather than reductionism can provide a more entire solution than a partial one. Historically, practitioners have been concerned about what Toyota is doing now rather than what was Toyota doing when TPS did not exist. Pioneers like Taiichi Ohno, the father of TPS and one of his close friends, Sheigo Shingo, an industrial engineering consultant to Toyota during the time, are less received and noted for developing TPS. In very simple terms, not to make TPS any more complicated than what it needs to be, TPS is an old way of thinking. In Ohno's book (Ohno, 1988), named the Toyota Production System, Ohno firmly believed that TPS is simply a form of industrial engineering (IE) aimed at reducing cost through systematic study. By treating everything as a process, Ohno and Shingo built the Journal of Industrial Engineering and Management - http://dx.doi.org/10.3926/jiem.293 - 773 - interconnections of TPS one by one, but more importantly passed on this industrial engineering way of thinking to future generations. The purpose of this work is to evaluate and quantify some of Toyota's thinking styles as it relates to Ohno's traditional view of TPS. It is speculated that one of the ways Toyota is able to develop such a holistic approach to TPS is by passing down from generation to generation a type of thinking similar to industrial engineering. Managers throughout Toyota are believed to teach, share and develop this kaizen mind to encourage systematic study and evaluation of business practices. The secondary goal of this work is apply a new form of management science, named dimensional reduction analysis to highlight and quantify managerial preferences. This work is expected to substantiate quantitatively many of Toyota's perceived industrial engineering practices, but also indicate the particular form. Meaning, most outsiders view lean as an extremely sophisticated form of industrial engineering mainly due to the influences of six sigma, lean sigma and now the popularized kaizen specialist. Due to these latest trends, one could dispute that the flavor of industrial engineering is very different from Ohno's more practical view of productivity improvement. This work is expected to bring insight and hopefully simplicity into understanding an old familiar way of thinking about problems from an industrial engineering viewpoint that acts as a catalyst for making the TPS system come alive. In this work the link will between TPS and IE will be established and analyzed to determine which trend of IE practices are utilized to maintain the TPS structure.