Managing the quality circle process: A new investigation of Toyota's QC practices

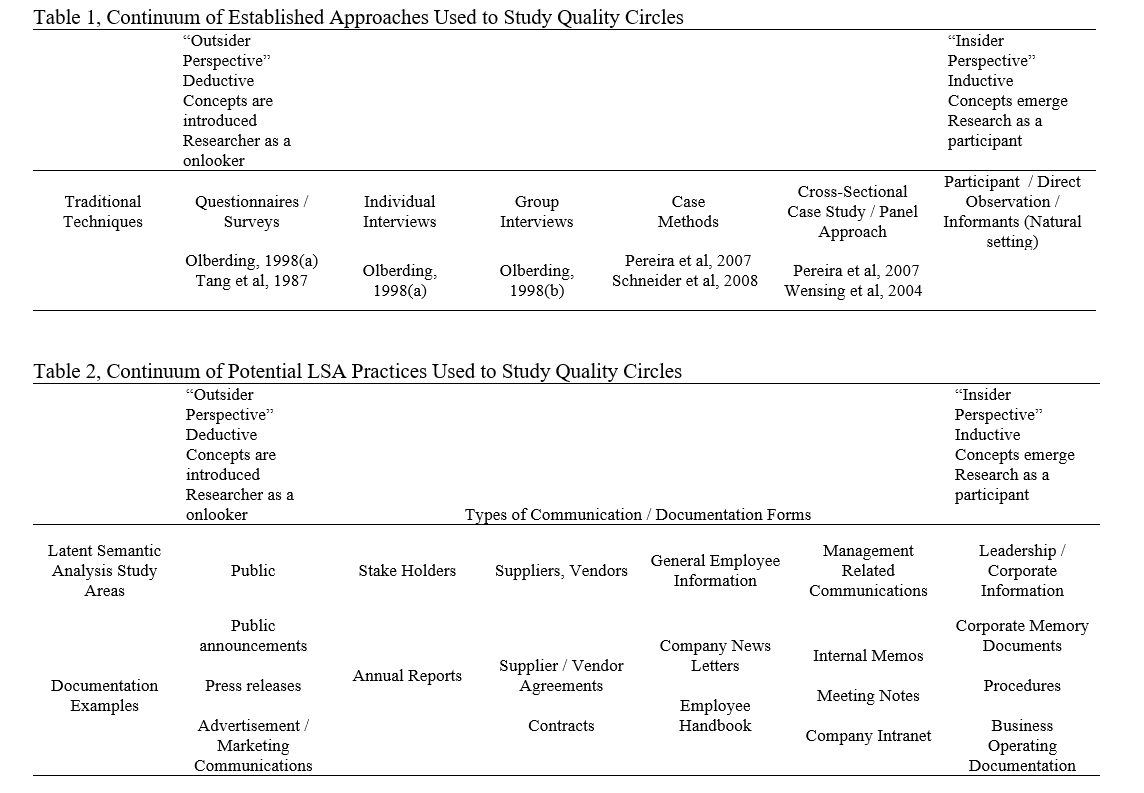

Quality circles (QCs) originated in Japan and have been adopted by the US companies since 1970s, which is generally recognised to have numerous benefits including increased productivity, raised employee motivation and cost reduction. While many companies try to follow Toyota's success by formulating similar QCs, many practitioners are not aware of the emphasis of QCs that Toyota focuses on. This work investigates the QCs programme in Toyota to discover why QCs can achieve success in Toyota and the difficulty of implementing them in other companies. This paper utilises a form of data mining technique as latent semantic analysis to analyse Toyota's achievement in QCs. This work examines the importance of the outcomes for QCs, and one of them is the learning of each individual within the circles rather than the actual results produced from the circles. These new insights will provide an increased understanding of Toyota's QCs programme.